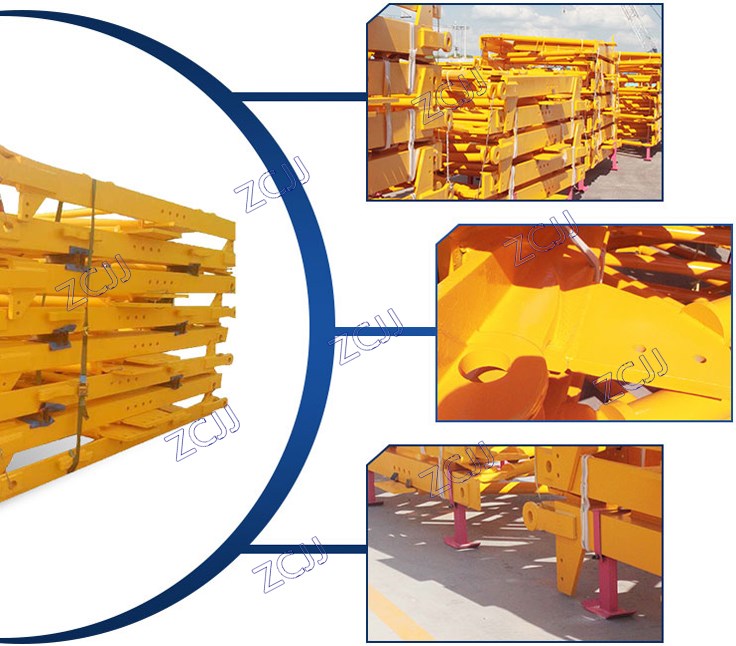

L69 Mast Section For Tower Crane Masts

- ZCJJ

- China

- 10days

- 50pcs

Addis Ababa Tower crane, Aesetta Tower crane,

Bachdal Tower crane, Asosa Tower crane,

Gambella Tower crane, Hallele Tower crane,

Products Specification

Type , Model: L69 Mast Section For Tower Crane Masts

Size: 2mx2mx3m

Materials: Q345B

Within: Pins, bolts, Ladder, Platform

Process: Blasting derusting,

Painting: Under painting , Middle painting, Surface painting.

Our factory produce and supply almost all famous brand tower crane :Mast section, Anchor Frame, Fixing angle ,Adaptor and so on as good quality and price.

L69 Mast Section For Tower Crane Masts

Tower Crane Knowledge sharing:

Characteristics and application of the reinforced concrete foundation of Tower suspension

The main products of the company are tower hanging QTZ80, tower hanging QTZ63(TC5610), tower hanging QTZ40(TC 5008), tower hanging QTZ31 .5, tower hanging QTZ25, tower hanging QTG20A series tower hanging, JZ, JS series concrete mixer,

There are dozens of construction machinery products such as PLD series batching machines, WJ80, WJ60 material lifters, etc.. The products are sold throughout the country and are exported to many countries and regions abroad.

Tower suspension type reinforced concrete foundation

L69 Mast Section For Tower Crane Masts

The construction unit shall review the foundation bearing capacity of the tower crane foundation according to the requirements of the tower crane manual and the geological conditions of the installation site before the tower crane is installed to ensure the safety of the tower crane installation and use.

The bearing capacity of foundation in different areas is very different. Therefore, we must review the bearing capacity of foundation under the concrete foundation of tower crane.

When the carrying capacity of foundation does not meet the strength requirements stipulated in the manual, corresponding technical measures such as supplementary pile foundation should be taken to make up for it.

The fixed tower crane of the cross beam foundation can also use a split reinforced concrete foundation. The four corners of the cross beam base of the tower crane are installed on the basis of four reinforced concrete.

The size of concrete should be determined by the strength of the foundation under the concrete foundation. Different types of Tower hoists shall determine the side length and height of concrete foundation according to the requirements of the tower hoist usage instructions.

L69 Mast Section For Tower Crane Masts

Reinforced bars and reinforcing bars in partitioned concrete foundations must be executed using instructions. If there are special requirements, the construction unit should carry out the strength design and provide specific technical documents to implement the construction.

With heavy science and technology as the background, the high-level corporate culture is integrated into the lives of employees. The ink depicts the people-oriented management concept and the backbone of the real gold forging crane industry.

Look at the same and different points of various models from the top structure of the tower crane

Tower hanging has been developed in China so far. There are nearly a thousand companies that produce tower hanging and tower hanging accessories.

Various tower hanging models emerge one after another, and the uses are very different. One of the important distinguishing criteria is the top structure of Tower hanging. The top structure of the tower crane mainly refers to the structure combination of the boom, tower cap and balance arm.

1. cantilever structure(flat head tower crane)

Stress: The lifting arm and the balancing arm of the flat head tower crane belong to the static structure of the cantilever. The mechanical model is single and the calculation is simple. The internal force is larger under the same load.

Amount of steel structure: because of the cantilever force, it is compared with other structural forms.

L69 Mast Section For Tower Crane Masts

Manufacturing: No tower cap, pull rod and other structure manufacturing simple.

Installation and disassembly: low installation height requirements, reduce the requirements for lifting equipment during installation and disassembly, save the cost and time for disassembly, and facilitate aerial disassembly;

Suitable for cross operation of cluster towers; It is suitable for situations where there are special requirements for height.

2. fixed tower cap, static external extension structure balance arm, single suspension point static structure boom structure

Force: more complex than the flat head tower hanging, more simple than double hanging points.

Amount of steel structure: materials in Pingtou Province; But it's more than a double hang.

Manufacturing: Fixed tower cap manufacturing complex; The balance arm is simple for the planar structure;

Installation and disassembly: high installation height required; Installation and disassembly are more complex than flat heads.

3. fixed tower cap, static extension structure balance arm, double suspension point one Super static crane structure

Stress: The load of the lifting arm for a super-static structure is more complex than that of a single suspension point.

Use of steel structure: For a super-static structure, the most economical material.

Manufacturing: Fixed tower cap manufacturing complex; The balance arm is simple to make for a planar structure.

4. piece tower cap, static cantilever structure balance arm, single suspension static structure boom structure

Stress: The stress analysis of the flat head tower is more complicated, but it is still a static structure.

L69 Mast Section For Tower Crane Masts

The lifting arm lever, balancing arm lever and sheet tower cap are added, and the lifting arm and balancing arm force are changed.

Amount of steel structure: static structure than Pingtou provincial materials; But it's more than a double hang.

Manufacturing: the sheet tower cap structure is simpler than the fixed tower cap, and the balance arm is more complex than the fixed balance arm.

Installation and disassembly high installation height required; Installation and disassembly are more complex than flat heads.

5, piece tower cap, static cantilever structure balance arm, double suspension point one Super static cantilever structure

Stress: The load of the lifting arm for a super-static structure is more complex than that of a single suspension point.

Use of steel structure: the crane is a super-static structure, the most economical material.

Manufacturing: the sheet tower cap structure is simpler than the fixed tower cap, and the balance arm is more complex than the fixed balance arm.

The double suspension structure requires high machining precision of two pull rods.

Installation and disassembly: high installation height required; Installation and disassembly are more complex than flat heads

On the Advanced of the Design Concept of Standard Festival of Tower Hang

The part of the tower tower body consists of the height of the base frame, Foundation section, reinforcement section, standard section, and half section. In the tower crane accessories, the tower crane standard section is the main force component and is also an important part of the lifting tower.

The combination design refers to the grouping of series products. Different products or the same product structure in the group can achieve a certain degree of interchange combination to form a new tower crane, thus greatly saving resources and improving the installation efficiency of the tower crane.

This combination design concept is particularly prominent in the tower crane standard festival.

As we all know, the standard section of the tower crane is the most interchangeable combination.

The advantage of standard section swaps is that they can first reduce material idleness. For example, when the small tower standard section has insufficient reserves, the idle large tower standard section is used.

Secondly, the large tower standard festival is used as the base section of the small tower to increase the independent height of the small tower and can also meet the needs of special projects.

For example, the standard section of TC 7040 can be used as the standard section of TC7030. The independent height of 7030 can be increased from the original 48 meters to 66 meters.

YONGMAO STT983 Mast section

YONGMAO STT753 Mast section

YONGMAO STT553 Mast section

YONGMAO STT403 Mast section

YONGMAO STT293 Mast section

YONGMAO STT253 Mast section

YONGMAO STT200 Mast section

YONGMAO ST80/238 Mast section

YONGMAO ST80/160 Mast section

YONGMAO ST80/116 Mast section

YONGMAO ST80/75 Mast section

YONGMAO ST80/60 Mast section

YONGMAO ST80/31 Mast section

YONGMAO ST70/50 Mast section

YONGMAO ST75/32 Mast section

YONGMAO ST70/32 Mast section

YONGMAO STL720 Mast section

YONGMAO STL660 Mast section

YONGMAO STL530 Mast section

YONGMAO STL420 Mast section

YONGMAO STL420A Mast section

YONGMAO STL330 Mast section

YONGMAO STL230 Mast section

YONGMAO STL203C Mast section

YONGMAO STL180 Mast section

SYM S315K16 Mast section

SYM S315K18 Mast section

SYM S315K16B(QTZ315) Mast section

SYM K50/50(QTZ450) Mast section

SYM K50/50B(QTZ450) Mast section

SYM K50/50C(QTZ450) Mast section

SYM K50/70(QTZ500) Mast section

SYM K50/70B(QTZ500) Mast section

SYM S450L25(QTZ450) Mast section

SYM S450L25B(QTZ450) Mast section

SYM S560K25(QTZ560) Mast section

SYM S560K25B(QTZ560) Mast section

SYM S650H24(QTZ500) Mast section

SYM S650M25(QTZ650) Mast section

SYM S650M25B(QTZ650) Mast section

SYM S650M32(QTZ650) Mast section

SYM S650M32B(QTZ650) Mast section

SCM C3208 Mast section

SCM D650 Mast section

SCM D360 Mast section

SCM D320 Mast section

SCM D230 Mast section

SCM D160 Mast section

SCM D120 Mast section

SCM D120 (A) Mast section

SCM D90 Mast section

SCM D60 Mast section

SCM P2200 Mast section

SCM P1200 Mast section

SCM P900 Mast section

SCM P600 Mast section

SCM P360 Mast section

SCM P8042 Mast section

SCM P8030 Mast section

SCM P7527 Mast section